Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Benefits

Wide range of colours

System Information

| Packaging: | 20 kg per bag (DF100) |

|---|---|

| 10 litre & 20 litre per pail (DF100 Emulsion) | |

| 1 litre, 5 litre & 20 litre per pail (Acrylic Sealer) | |

| Consumption: | 2 - 3 kg per sq mtr per mm (Trowel On) |

| 1 - 1.5 kg per sq mtr per coat (Spray On) | |

| 4 sq mtr per litre (Acrylic Sealer) |

Instruction for Use

SURFACE PREPARATION

The concrete surface to receive the MASTERPAV DF100 Polymer Resurfacing shall preferably by mechanical scabbling to achieve a concrete surface profile (CSP) 3-4 as recommended by ICRI.

The surface should be cleaned and free of any debris or dust.

If there are cracks in the substrate, it should be rectified. Very often the applicator incorporates them into the pattern of the finished topping.

PRIMER- MASTERPAV DF100 Emulsion

The clean surface shall be primed with 1 part MASTERPAV DF100 Emulsion to 1 part water with a pump sprayer and then brushed or rolled into the surface. Allow the primer to dry to the touch or become tack free before applying the base coat.

BASECOAT- MASTERPAV DF100 Base coat

- Add 5.2 to 5.5 litres of MASTERPAV DF100 Emulsion into a clean 20 litre plastic pail.

- Slowly mix while adding the 20 kg MASTERPAV DF100 (powder) into the pail. Recommended mixing speed 300 - 400 rpm.

- Mix into a homogeneous and allow 1 to 2 minutes for the materials to settle down.

- The mixed materials is then poured out and troweled. Recommended usage 2 to 3 kg/m² per coat (depending on the floor substrate).

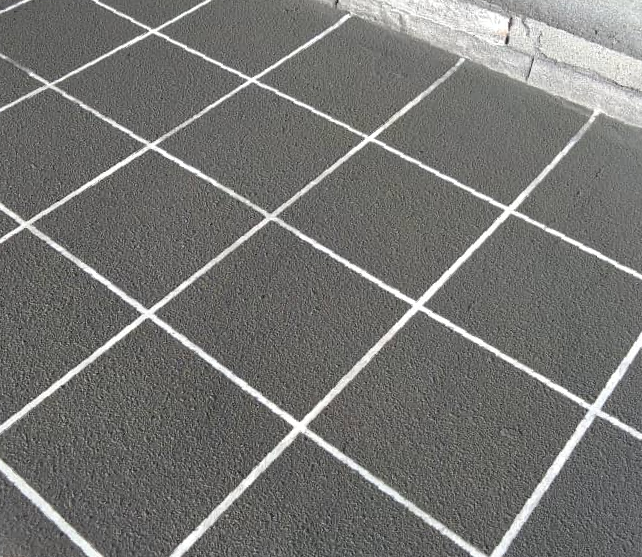

TAPPING & DESIGN

After the base coat has dried out (normally 24 hours) clean the surface and commence the required pattern & design with stencils or filament tape. It is recommended that the tapping & design work is done for the proposed day’s work of the MASTERPAV DF100 Top Coat.

TOPCOAT- MASTERPAV DF100 Top Coat

- Apply intercoat primer at 1 part MASTERPAV DF100 Emulsion to 1 part water with a pump sprayer and then brushed or rolled into the surface.

- Add 5.2 to 5.5 litres of MASTERPAV DF100 Emulsion into a clean 20 litre plastic pail.

- Slowly mix while adding the 20 kg MASTERPAV DF100 (powder) into the pail. Recommended mixing speed 300 - 400 rpm.

- Mix into a homogeneous and allow 1 to 2 minutes for the materials to settle down.

- The mixed materials is then poured into a hopper gun and spray to finish.

- When the 1st coat has dried out (1 to 2 hours), spray on the 2nd coat over the 1st coat. Recommended usage is 1 to 1.5 kg/m² per coat.

- Upon completion (1 to 2 hours), remove the stencil or filament on the day itself, blow off all the loose materials.

- Light sanding with a sanding stone over the surface.

SEALER APPLICATION

Allow the system to set (normally 24 hours) & apply additional 2 coats of MASTERPAV Acrylic Sealer. Allow first coat to dry before applying the 2nd coat. After sealing it is recommended that the sealer surface shall be protected from traffic.

603-8961 3798

6017 - 630 2377

6012 - 9393 143

MASTER MATERIALS MANUFACTURING SDN BHD (203747-T)

Lot 1826, Jalan KPB 1, Kws. Perindustrian Kg. Baru Balakong,

43300 Seri Kembangan, Selangor Darul Ehsan,

Malaysia

enquiry@mastermaterials.com

All Rights Reserved | Master Materials Manufacturing Sdn Bhd

Designed by Trinity42