Slide title

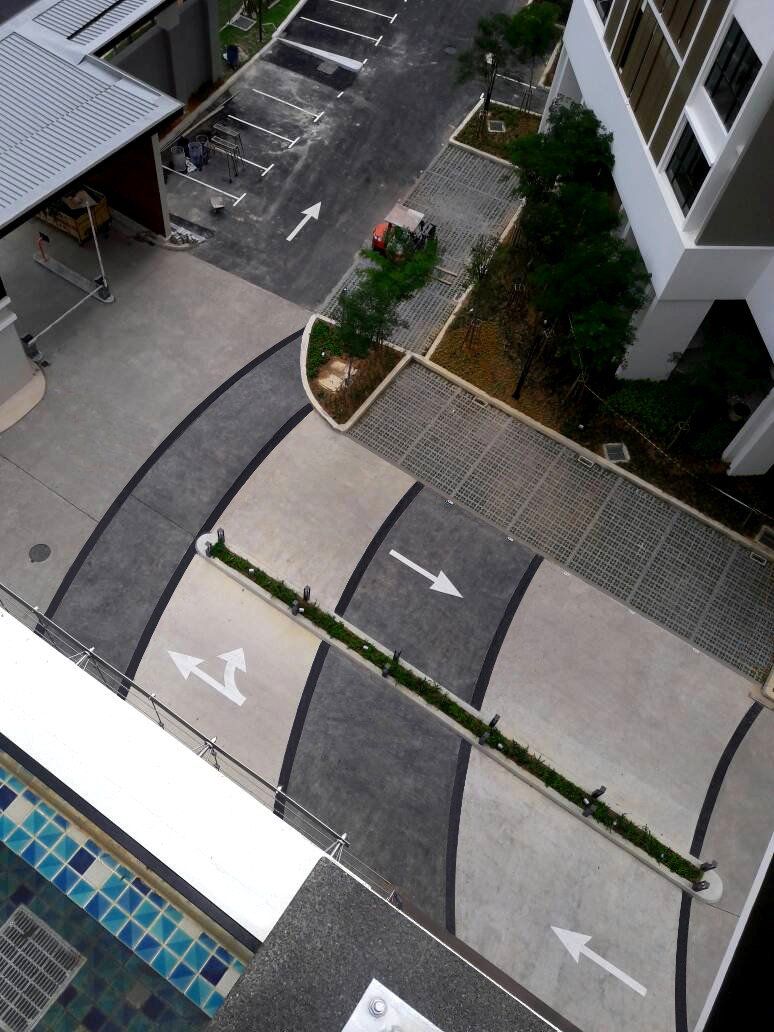

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Benefits

System Information

| Packaging: | 20 kg per bag (Aggregate) |

|---|---|

| 10 litre & 20 litre per pail (SW1.0) | |

| 1 litre, 5 litre & 20 litre per pail (Acrylic Sealer) | |

| Consumption: | 7 - 8 kg per sq mtr (Aggregate) |

| 4 sq mtr per litre (Acrylic Sealer) |

Instruction for Use

SURFACE PREPARATION

Prepare and lay the fresh concrete as per requirements. Note that the concrete must be a minimum of G25 or compressive strength of 25 N/mm².

After the concrete has been screeded, consolidated and further level by bull float. Ensure that any free water present has evaporated or removed in order to proceed to application.

APPLICATION

Broadcast the Treated Aggregate (15 - 20 mm) evenly over the surface.

WASHING - SW1.0

After 3 - 7 days of curing, use MASTERPAV SW1.0 to wash the concrete surface. It is recommended that MASTERPAV SW1.0 be diluted with 1 part SW1.0 to 1/2 part water, but this ratio will depend on the conditions on site. This is to expose the aggregate effect of the floor. This is also important to prevent any dust to stick on the surface, which it will affect the bonding of sealer and the floor.

SEALING

After the floor is dried, apply MASTERPAV Acrylic Sealer for a high gloss, gloss, semi-gloss or matte finishing. Application of MASTERPAV Primer Sealer AS20 is highly recommended before the application of 2nd coat Acrylic Sealer.

603-8961 3798

6017 - 630 2377

6012 - 9393 143

MASTER MATERIALS MANUFACTURING SDN BHD (203747-T)

Lot 1826, Jalan KPB 1, Kws. Perindustrian Kg. Baru Balakong,

43300 Seri Kembangan, Selangor Darul Ehsan,

Malaysia

enquiry@mastermaterials.com

All Rights Reserved | Master Materials Manufacturing Sdn Bhd

Designed by Trinity42