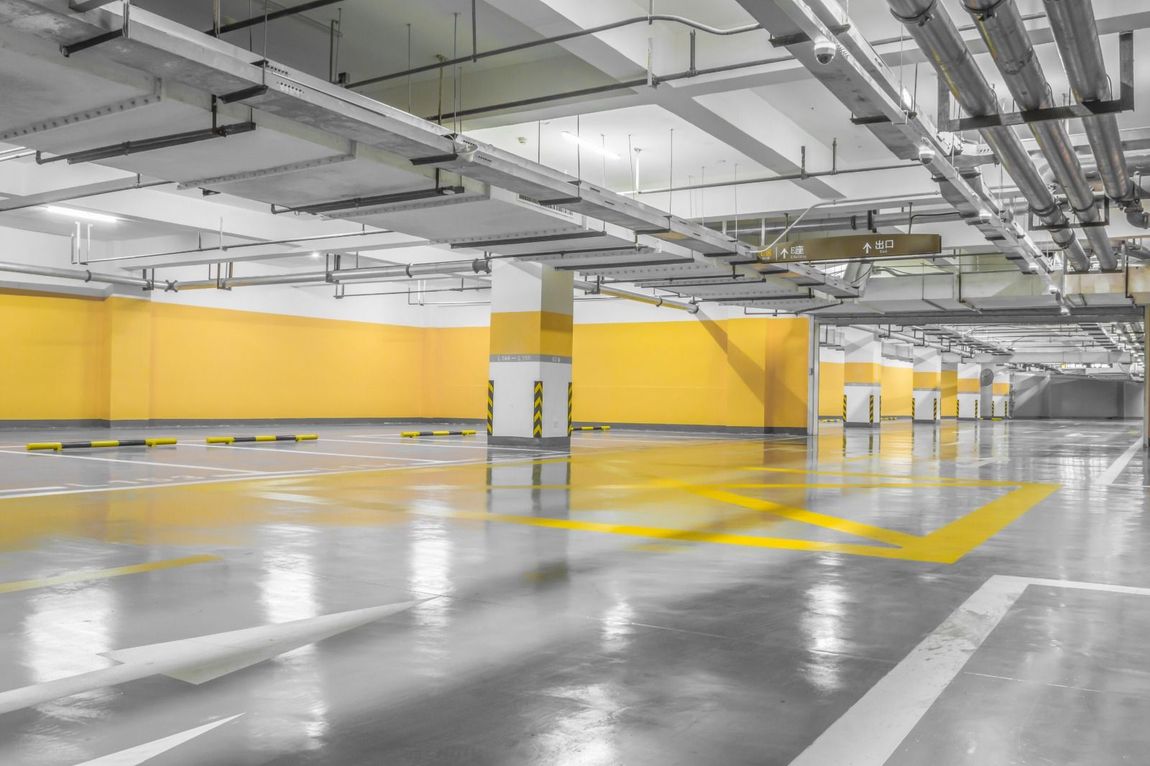

DECORATIVE CONCRETE COATING

MASTERPAV Roll-On Epoxy System is a solvent-free epoxy coating system suitable for rolling applications. It is to be used as a thin topping or broadcast coat on a primed surface.The system comprises MASTERPAV EC10 SF Epoxy Primer as an undercoat and MASTERPAV EC13 SF Epoxy Coating as a finished coat that comes in a wide range of attractive colours. It is ideal for DIY floor projects.

BENEFITS

Solvent-free, low odour

Good mechanical & chemical resistance

Seamless – prevents ingress of chemicals into the substrate and prevents bacterial growth

Hygienic – provide easy to clean dust free surface

Environmentally friendly

Available in variety of colours

SYSTEM INFORMATION

PACKAGING

MASTERPAV EC10 SF EPOXY PRIMER

4.5 & 1.0 kg/set

MASTERPAV EC13 SF EPOXY COATING

4.5 & 22.5 kg/set

CONSUMPTION & COVERAGE

MASTERPAV EC10 SF EPOXY PRIMER

0.3 kg/m2

MASTERPAV EC13 SF EPOXY COATING

0.5 kg/m

INSTRUCTION FOR USE

SURFACE PREPARATION

The concrete surface to receive the MASTERPAV EC13 SF Epoxy Coating shall be subjected to mechanical grinding to achieve a concrete surface profile (CSP) 1 – 3 as recommended by ICRI.

It is recommended to conduct a concrete moisture test before the application of MASTERPAV EC13 SF Epoxy Coating. Concrete substrate shall have a moisture content of a maximum of 4%. For concrete substrates with moisture content higher than 4%, a moisture barrier is recommended.

All cracks are to be rectified before actual application.

PRIMER: MASTERPAV EC10

Pour the entire content of Part B into Part A of MASTERPAV EC10.

Mechanically mix the mixture using a low-power mixer until homogeneous.

Apply the mixed material using the suitable roller and allow it to dry overnight.

TOPCOAT: MASTERPAV EC13

A) MASTERPAV EC13 as Thin topping

The previously applied primer should be cured, dry to the touch, and no longer tacky.

Light sanding the surface (promotes good bond between coats), followed by vacuuming.

Wipe clean the dust using a microfiber wipe with a suitable solvent (eg: MASTERPAV Thinner 101)

Pour the entire content of Part B into Part A of MASTERPAV EC13.

Mechanically mix the mixture using a low-power mixer until homogeneous.

By using the suitable roller, roll the mixed material evenly over the entire area at the recommended coverage.

Let the coating dry for 12 hours.

B) MASTERPAV EC13 as broadcast coat

The previously applied primer should be cured, dry to the touch, and no longer tacky.

Light sanding the surface (promotes good bond between coats), followed by vacuuming.

Wipe clean the dust using a microfiber wipe with a suitable solvent (eg: MASTERPAV Thinner 101).

Stir Part A thoroughly and add Part B in the right mixing ratio.

Mixing shall be done with a low-speed power mixer until homogeneous.

Apply the first coat of MASTERPAV EC13 using a short hair roller evenly over the entire area.

When the first coat is still wet, immediately broadcast the quartz in an oversaturated manner on top of the first coat (Note: broadcast method: sprinkle the quartz up in the air rather than throwing it down into the ground) and let it dry overnight.

Sweep off all loosely bound quartz sitting on the surface using a suitable method (eg: floor scraper) and follow by vacuuming the entire surface to make sure there are minimal remnants of loosely bound quartz before applying the second coat of MASTERPAV EC13.

Let the second coat dry for 12 hours.

PROTECTION

After application, it is recommended that the coated surface shall be protected from:

Foot traffic for a minimum of 24 hours after application;

Light vehicle traffic for a minimum of 7 days after application;

REFER TO PRODUCT